Description

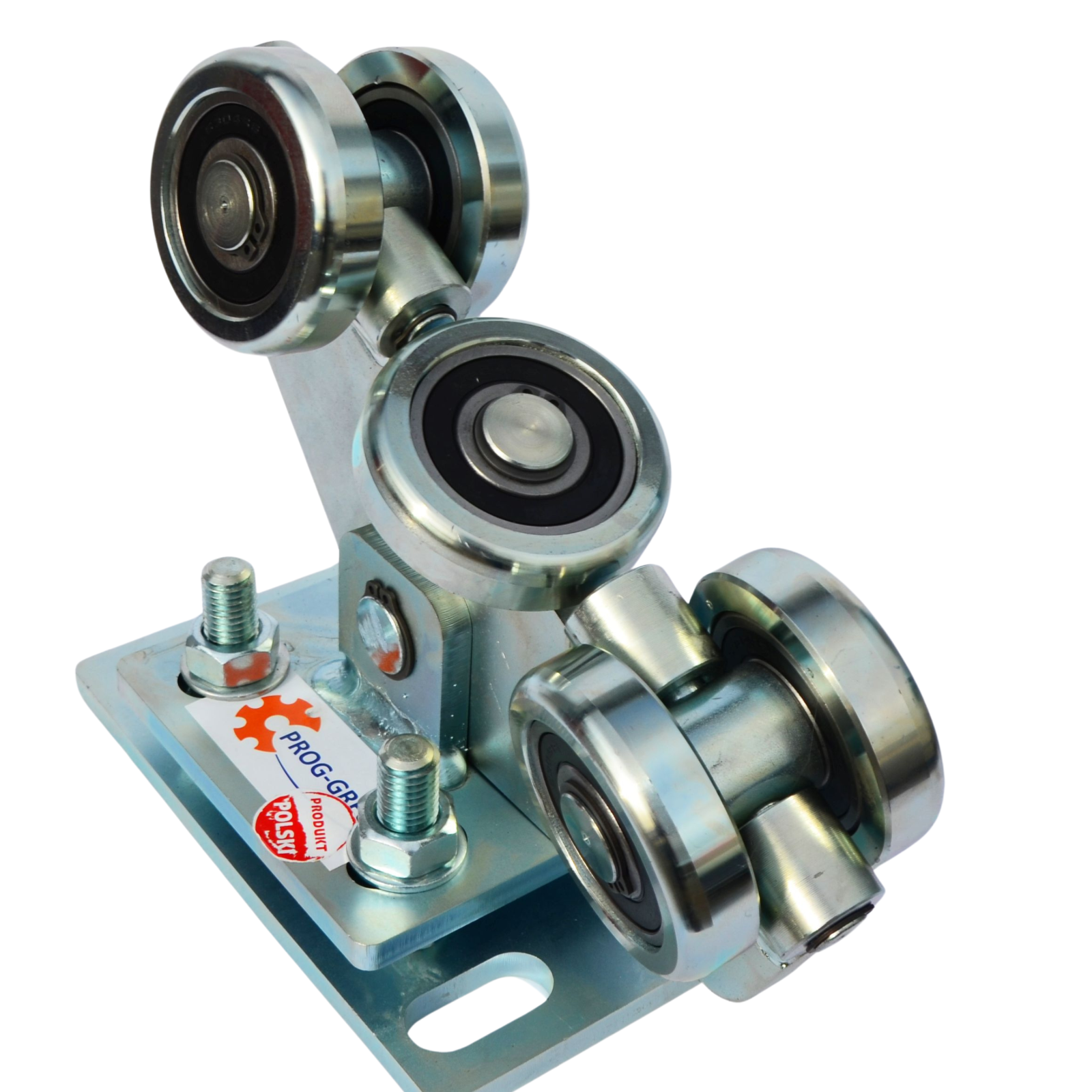

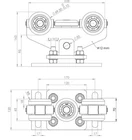

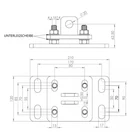

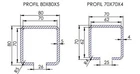

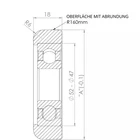

Szablon Aukcji eBay Trolley for sliding gate 80 x 80 x 5 with 2 adjustable base plates Patented Design - Highest Quality and Reliability Price for 1 piece trolley!!! Proper operation of the gate requires the installation of 2 Carriages , and only in this case can we provide a smooth and smooth running guarantee, regardless of the quality of the gate itself. ⭐ Patent Protected Design We are happy to provide you with a innovative design offer, where not only the vertical plate (as with other trolleys), but also both pairs of rollers swivel mounted. Our listing is for Gate Manufacturer , Wholesaler , Hardware Stores as well as Private customers . Limited time listing. Soon our trolleys will only be available in select stores and wholesalers across the country. Watch our video to see how our trolleys work: https://youtu.be/4JaiodCPcCE Trolley castors for sliding gate 80 x 80 x 5 If you have a problem with a Gate that moves hard or annoyingly jams in certain places? The cause may be a poorly working trolley be. The guides that make the gates are not perfect. You can even contact yourself a few months after installing the gate twist . The reasons for this are Voltage , which during the production of the profile as well as through the Welds arise. Our trolleys are resistant to such issues as we 2 swivel, independent joints insert on the guide rollers, which Compensate tread unevenness . Our customers replace classic trolley (with rigidly mounted castors) through our if your gate clamps or damaged has been (e.g. when a courier drives backwards and overlooks the gate). In almost 100% of cases replacing the carriages solves the problem. Very often it happens that the gate is only located on a certain section heavily moved . Setting classic carriages does not produce the desired effect in many cases, and the only solution is the Heating the guide and the manual straightening . However, the Paint and zinc plating damaged . So the problem will only partially solved , as the gate can be "straightened" but after some time the problem recurs. Do not engage in such solutions. Hire the gate manufacturer to install swivel trolley with articulated . An investment , and the problem of a hard-running door will no longer affect you. ⭐ ATTENTION!!! The specified Rail Dimension will measured outside , not within the profile. This auction is for a Trolley for the profile 80x80x5 . Technical Parameters: Distance of bolts in foundation plate: A = 170mm, W = 70mm Additionally: 2 base plates for easier Height Adjustment of the gate Material: All elements are made of high quality steel and galvanised Bearing: Carriages come with 6304 2RS bearings equipped, the maximum size available, which protects them very well from the accumulation of sand and other contaminants Weight of a trolley: 10kg Carriage Load Capacity: Up to 2500kg Guide Rollers: Made of very high quality material, with increased hardness and Abrasion Resistance Construction: Designed to disassemble each item and, if required, replaced can be In many cases, there is a replacement of a Standard Trolley against a with joint only in it, the middle bolt , which connects the base plate to the body, remove and replace it with ours. It is then not necessary to drill new holes in the foundation plate for the bolts. The only condition is that the Body Thickness of the previously installed trolley 12mm is and the Center Bolt Diameter 20mm (in most cases these parameters are met). ⭐ In many cases, there is a replacement of a Standard Trolley against a with joint only in it, the middle bolt , which connects the base plate to the body, remove and replace it with ours. The only condition is that the Body Thickness of the previously installed carriage is 12mm and the Center Bolt Diameter 20mm (in most cases these parameters are met). Carriage Advantages: ⭐ Profile Twists: The guide profile may be twisted or warped by welds; this has no influence on the function of the carriages. The gate will still slightly along the entire length move (Fig. 1 - Traditional, Fig. 2 - New Construction). ⭐ Gate Deformations: The gate itself may be warped, unclean or inaccurate; this also affects not the function of the carriages. ⭐ Even Load Distribution: The load is always evenly distributed over each of the four castors , none of the wheels are ever overloaded. Picture Name: 1.1 - Twisting Guide 1.2 - Maximum rotation angle of the guide 1° 1.3 - Rigid mounted rollers clamp in the guide 1.4 - Twisting Guide 1.5 - Maximum rotation angle of the guide 11° 1.6 - Even roller spacing even adapts to a heavily twisted guide How do you adjust the height of the carriages? During the installation of the gate, it is necessary to adjust the carriages to different heights. Often the foundation is not evenly cast. We have equipped our trolleys with 2 base plates that facilitate the height adjustment of the gate. It is always easier to put the gate slightly higher by pressing it as shown in Fig. 9 mounted than to press the foundation if the gap under the gate was too large. Drill Holes in the foundation plate, e.g. for M16 bolts. Anchor them permanently , e.g. with chemical dowels. Attach the first base plate directly on the foundation slab. The second base plate is used to adjust the door to the appropriate height. Lock the nuts from above , to secure the setting. ⭐ Name of the above picture: 1.1 - Guide Twist Angle 1.2 - Start of Lead 1.3 - End of Guide 2.1 - Top view of gate 2.2 - The C profile of the guide roller is not in a plane with the guide 2.3 - Guide ⭐ Why such trolleys? Our years of experience in the fence industry has led us to develop a trolley with such capabilities. Often we have assembled a gate that was manufactured with the utmost care, and despite the laborious adjustment of the carriages, the gate moved with Resistance , e.g. on the section from the middle of the gate until closing. After adjusting the carriages in this position, the gate moves lightweight on this section, but began to deal with Resistance move on the section from center to opening where it previously moved slightly. This is a typical behavior of a gate with warped guide profile or the gate itself. You cannot adjust such a gate on ordinary carriages!!! ⭐ What causes the deformation of the guide and the entire gate? The Standard and most popular gate profile (semi-closed C-profile 80x80x5 with gap 27.5mm ) is cheap and solid. Unfortunately manufacturing does Rollers to Voltage in the steel structure, which, when combined with welds, makes the profile deform . These stresses are easily seen when you cut through the guide profile - the ends "spread" due to the stresses. Often you will also encounter factory twisted profiles ("warped", Fig. 4 ). A twist of only 5° blocks the door completely on ordinary trolley, and on a length of 6m it is virtually invisible. Gate profiles from different manufacturers are usually produced by rollers. Torsional stresses will not be replaced by a Press brake introduced, but this is a much more expensive process. The Deformation of the entire gate , which affects its movement, is that its Plane Twisted so that the guide profile and C-profile of the guide roller not in one level lie ( Fig. 5 ). Then the guide roller pulls the door once to one side and once to the other side of the carriages. A common problem, especially with long gates . ⭐ Construction Our trolleys come standard for large loads designed. Therefore, we manufacture the Metal-only castors , profiled accordingly so that the load is always on the Center of bearing is transferred. They come with hermetically sealed, waterproof bearings equipped with a Metal Rubber Gasket sealed (not just with a metal plate). This guarantees that Do not penetrate dust and moisture , and the lubricant included does not age . The size of the bearings is the largest , which can be used for the 80x80x5 profile. Thanks to the unique construction distributes the Load Force on the trolley always evenly on all four rollers, regardless of how much the guide is warped. Therefore, none of the bearings ever overloaded !!! In a ordinary trolley it is impossible for all rollers to always be evenly loaded as they rigidly mounted are. The more wheels in the trolley, the larger this Discrepancy . Carriages and guides are not precision elements; with ordinary carriages, it happens that a protruding roller carries most of the load. You can easily tell by turning an ordinary trolley with the rollers down and rolling it over a flat surface - some wheels still do not spin !!! Thanks to the unique construction of our carriages is their Load Capacity up to: ⭐ 2500kg!!! For example, the required load capacity of a trolley for a gate with a Passage width of 6 m and a weight of 600kg approx. 1500kg (with a carriage distance of 2 m, details in the brochure). Remember - Do not buy trolleys without a load capacity specified by the manufacturer. Note - the required load capacity of the trolley can not just based on the weight of the gate be chosen! It is necessary to use the Distance of carriages (length of counterweight). Buy It Now