Description

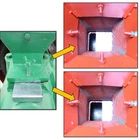

新建网页 2 Corn Peeling and Grinding Machine Corn Maize Milling Huller Peeling Machine 220V The corn peeling and grinding machine is an indispensable device in modern corn processing. By means of the efficient peeling and grinding technology, corn kernels can be changed into high-quality corn grits with better taste, greatly meeting the needs of household application and small-scale commercial processing. The corn peeling and grinding machine has the advantages of integrated design, convenient operation, high efficiency and product quality and wide application, and is suitable for corn producing areas and the small-scale processing field. Voltage 220V/60HZ Three-phase electricity Motor power 5.5KW Rotating speed of motor 1440RPM Rotating speed of main shaft 950-1100RPM Size of roller Φ90mm*L180mm (3.5*7.1 inches) Number of rollers 2pcs Yield 400-500Kg/h Rate of finished products >70% Bran content <0.7% Fineness of finished products Level 2-3 Temperature rise of finished products ≤20˚C Machine size 90*48.5*124.5cm (35.4*19*49 inches) Net weight About 133Kg (293.2LBs) 1. Integrated design: Integrating the peeling and grinding processes into one machine, saving space and equipment investment. 2. High efficiency: Compared to traditional manual or step-by-step processing, it greatly improves the production efficiency. 3. Good quality of finished products: The peeled corn grits have a good color and fine taste, and are not prone to going bad. 4. Simple and convenient operation: Compact structure, and relatively standardized operation process. 5. Wide application: The machine is suitable for family workshops, small grain processing plants, food processing enterprises, etc. Features Feeding Hopper The enlarged feeding hopper is of a square pyramid structure, ensuring smooth feeding while reducing the material adding frequency and guaranteeing the processing continuity and uniformity. Feeding Control Plate The bottom feeding inlet is controlled to be opened and closed through the feeding control plate, and the opening size is manually adjustable and controllable, well adapting to different materials. Cover Plate The cover plate can also be moved to open and close the machine chamber, allowing the operator to observe the internal condition of the machine chamber in real time. Driving Motor The high-quality motor can provide stable driving force for peeling and grinding operation, can stably operate for a long time and has a long service life and low fault rate. Adjusting Knob The adjusting knob can be used to adjust the distance between the roller and the mesh screen to meet the processing requirements of different materials, and is easy to operate and use. Discharging Outlet The discharging outlet is designed to be of a step type structure, finished products can be smoothly discharged, and the material splashing phenomenon can be effectively avoided. Installation and Operation Method A. Installation Method 1. The machine should be installed in the room with good ventilation and appropriate temperature and without exposure to sun or rain. There should be a stable and flat foundation, and the foundation screws should also be tightened. There should be no vibration or swing during use. 2. During installation, the center of the belt pulley between the machine and the prime motor should be aligned and placed straightly. 3. After the peeling machine is installed, the idling test is conducted to check the installation condition and the main shaft heating degree, and please pay attention to whether the rotating direction accords with the direction indicated by the arrow. B. Operation Method 1. Before processing, the raw grains should be inspected, and no impurities are allowed to be mixed with the raw grains. When peeling corn and wheat, mix the raw materials with clean water, and wait for about ten minutes before peeling, so as to ensure the quality of peeling. 2. Open the machine cover, adjust the gap between the cutter and the roller, check if the screen bottom is intact and if there are any falling objects in the working chamber, then close the machine cover, tighten the hook screws, and close the sliding plate. 3. After starting the machine for half a minute, slowly open the sliding plate, adjust the discharge outlet, and process the grain. 4. When the processing operation is completed or the machine stops halfway, the feeding inlet sliding plate must be closed first, the machine operates for about one minute, and then the power can be cut off. 5. Adjust the gap (referring to the outer diameter) of the roller by adjusting the screw. Generally, the inlet is about 4-6 millimeters and the outlet is about 2-3 millimeters. If finding that the material is broken or the raw grain flows out, adjust the cutter gap and the size of the discharge outlet in a timely manner. The side, close to the feeding end, of the cutter is prone to wear and tear, and the sides of the cutter can be exchanged to be used. If there is excessive wear and it is difficult to ensure the processing quality, a new cutter should be replaced. 6. After the roller is used for a long time, the peeling rate and accuracy of the roller will significantly decrease due to excessive wear, and the roller should be replaced in a timely manner. 7. If the machine is stuck, immediately close the feeding inlet sliding plate, open the upper cover, clean away the raw materials in the the machine shell, rotate it smoothly, and then start the machine again. 8. The rotating speed of the peeling machine must be within the specified range, and then the machine can be started, as the too high or too low speed can affect the discharging quality and yield. If the speed is too high, the raw grain is prone to flowing out, and the quality will be reduced. The similar situation may also occur if the speed is too low. 9. Special attention should be paid to the adjustment of the rotating speed of the peeling machine, the gap of the cutter and the size of the discharge outlet, which are the three key factors related to quality and output, and should be taken into account. 10. If there are phenomenon that rice grains are sucked into the bran or the grains cannot be winnowed thoroughly in the working process, it is necessary to carefully check whether the bran outlet cloth bag is tightly tied or whether the filter sieve air outlet is blocked. Otherwise, corresponding troubleshooting should be carried out. 11. It is advisable to use a 2-meter cloth bag for the air outlet. If the wind is low, the bag can be lengthened. If the wind is strong, the bag can be tied to be shorter. Maintenance 1. Regularly pay attention to the fastening condition of each component, and all fasteners must not be loose. 2. Each lubrication part should be lubricated regularly with clean grease, and the temperature at the bearings should be regularly monitored. If the operator feels hot when touching the bearings, the machine should be stopped immediately for maintenance. 3. After use, the machine should be cleaned thoroughly. If the machine is not used for a long time, the outside of the machine should be coated with anti-rust oil. 4. If the machine stops for three hours or above, the belt should be removed. 1. Do not touch the running parts during operation. Do not put the hands into the machine. 2. There is no plug on the power cord. Please let a professional electrician conduct wiring operation. Ensure that the machine is reliably grounded. Item Number Corn Peeling And Grinding Machine--238043 Shipping & Handling Default Shipping Cost or Free Shipping Information: Default shipping cost or free shipping service is only for the lower 48 United States by UPS Ground or USPS. Other areas or needs other shipping ways, please contact us. Buyers from Guam, Puerto Rico, Virgin Islands, American Samoa, Alaska, Hawaii, PO Boxes, APO/FPO addresses or other countries/areas, there WILL be extra shipping costs, please contact us for more detailed information. Please make sure your address is valid for both UPS and USPS services. Any costs incurred because of incorrect or undeliverable address should be undertaken by buyer. Handling Time: Shipping is usually made in 1-3 business days after payments cleared. Orders are processed from Monday-Friday; Not on the weekends & public holidays. Sales tax / Customs duties Any sales taxes or Customs duties are not included. If came out, they must be undertaken by the buyer. Damage In Shipping Email or call us First! We will work with you to get the case resolved in the fastest method. Return&Refund If you are not 100% happy with your purchase, please contact Us. Please don't directly opened a request or case without informing us, or else, we will do some discounts on the warranty and other sales-services later on. Hope for your understanding. Returns & Exchanges All returns must be made within 30 days of delivery date. Items must be in new, unused condition, with all original materials included with the shipment. A partial refund may be applied for opened or damaged items, depending on the condition. Items returned under the buyer’s remorse: The return shipping fee must be covered by the buyer; The original shipping cost will also be deducted from the refund. 15% restocking fee of the items purchase price will be charged. Returns that are the result of our seller's error: Buyer will receive a full refund of the item as well as shipping charges All returns require a RA (Return Authorization) number that will be given by our seller. Please contact with us at first for more details. Defective & Damaged Products If product was received damaged or not as described, please send us some pictures or videos, so we could well understand your problem, then solve them for you ASAP. Besides, it's much helpful for us to claim with UPS, remind our related department to pay much more attention to packaging later on. Hope for your understanding. Replacement or refund of defective or damaged products can only be returned in exchange for the exact same product, or else, the purchase price will be refunded back to your original payment method. If an item is received damaged, customer service must be contacted within 7 days of receiving your item. All returns require a RA (Return Authorization) number as above. Warranty& Feedback 6 months' warranty for the machines, not for the consumables. We stand behind our products all the item, so even if your warranty period has expired, you can still seek for service or technical support from us with low cost. Any warranty shipping cost to us is responsible by buyer. Any shipping cost to buyer is responsible by the seller. We committee to the customer satisfaction and want to bring you the best purchase experience. If there is any problems, please contact us ASAP. If not, please leave us a positive feedback as it's very important for us. Thanks very much. On Dec 25, 2025 at 21:52:48 PST, seller added the following information:

Super fast shipping and extremely well packed. Showed up in perfect condition! The manuals on all of these machines are a little lacking in the translation, but some quick searches on youtube will get you going it you are not already familiar with how they work. Very pleased with the equipment and highly recommend the seller!

Description of the listing was accurate. Seller wrapped the item appropriately (standard mailer bag, which was sufficient for the item's protection), and there were no issues with shipping. Item arrived quickly. AAA+ seller, unlike some others I could name LOL! I would buy from this seller again in the future!

Item is as described, shipped in good time. Arrived in good condition, great value, quality and appearance. Good communications. Thanks, will buy again. Thanks for shipping USPS. It is the best way for me to receive items. Arrived in excellent time, ahead of delivery date.

Related products

VASTA Vegetables & Fruit Sheet Slicer KETO VEGAN VEGETARIAN Spin and Slice. Gray

$ 0.53Kattex Commercial Vegetable Chopper | Heavy Duty Food Dicer Onion Cutter

$ 35.9